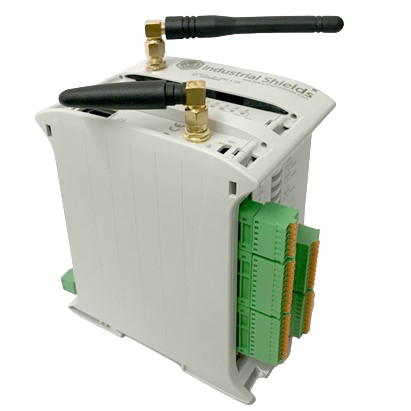

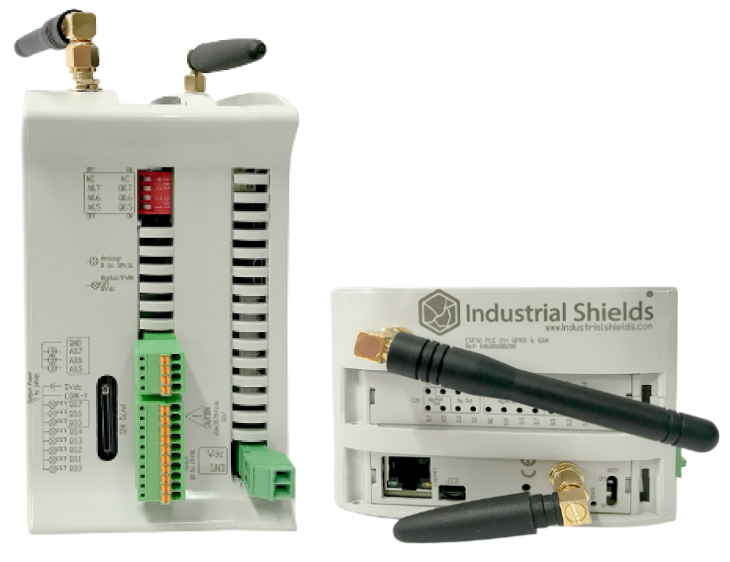

Meet the dual-core ESP32 PLC

A powerful and versatile board, ideal for industrial solutions of monitoring, control and automation.

The ESP32 board comes with dual core that allows you to separate the functions to:

By doing like this you can manage more data and do it faster.

Up to 520Kb SRAM memory available, ideal for support a huge range of industrial projects.

Go even further with external flash memory.

Up to 20 Inputs & Outputs

Digital, Analog and Relay. Security and Robustness

Standard Protocols

RTC, µSD, Ethernet, USB Full/Half Duplex RS485, RS232, I2C, Modbus

No License cost

Program using the Arduino IDE platform

Modular PLC

This is the first equipment based on the ESP32 technology designed for professional use. With the PLC range, you can have up to 58I/Os. It also contains several communication ports that provide more flexibility and control. The ESP32 PLC family offers the possibility to expand up to 127 modules through I2C, which means that you can have until 7100 Inputs / Outputs in Master-Slave connections, additionally to sensors, etc…

Programming Software

This ESP32 PLC can be programmed using the Arduino IDE platform.

Instantaneous connection and coding

The ESP32 PLC is programmed through the USB ports. This PLC can also be programmed through an Ethernet port remotely. This offers immediate access to program, maintain, and control.

AnESP32 Industrial grade shield

Multiple applications for multiple sectors.

With the ESP32 PLC create solutions for lots of projects.

Eolie. Energy. Sustainability

The use of renewable energy is increasing at cruising speed every passing day. Ensure the best performance of the installations monitoring the KPI.

Greenhouse

Control remotely the humidity, the ventilation, the C02 level and the luminosity. By doing this, you will maintain the best environment and get the best.

Machinery. Maintenance

Anticipate the failure or breakdown thanks to the monitoring and understanding of the critical indicators available.

lndustry 4.0

Obtain the necessary data and have visibility of them to start the analysis and decision-making. Also, implement the correction and improvement factors, in parallel with the continuous acquisition of data.

Logistics

Automate and control the different stages of the material collection and distribution process. Also, develop a server to store data and have remote control from anywhere.

Petrol. Chemistry

Get more information

If you are interested, have any doubts or questions, please fill out the form. We will get back to you as soon as possible.