SOLID STATE RELAYS

Solid State Relays offer reliability, speed, and longevity. Whether you’re dealing with DIGITAL or ANALOG control, SSRs provide efficient switching without the limitations of mechanical relays.

Remember, SSRs are the silent heroes of electrical control, quietly ensuring seamless operations without any moving parts!

Digital SSR

SC Series

SC Series Solid State Relays are ready to use and to be mounted on industrial DIN rail.

The integrated heat sink is designed to drive up to 25A @240Vac, resistive loads, up to 40°C of Ambient temperature or 10A @240Vac with 80°C of ambient temperature.

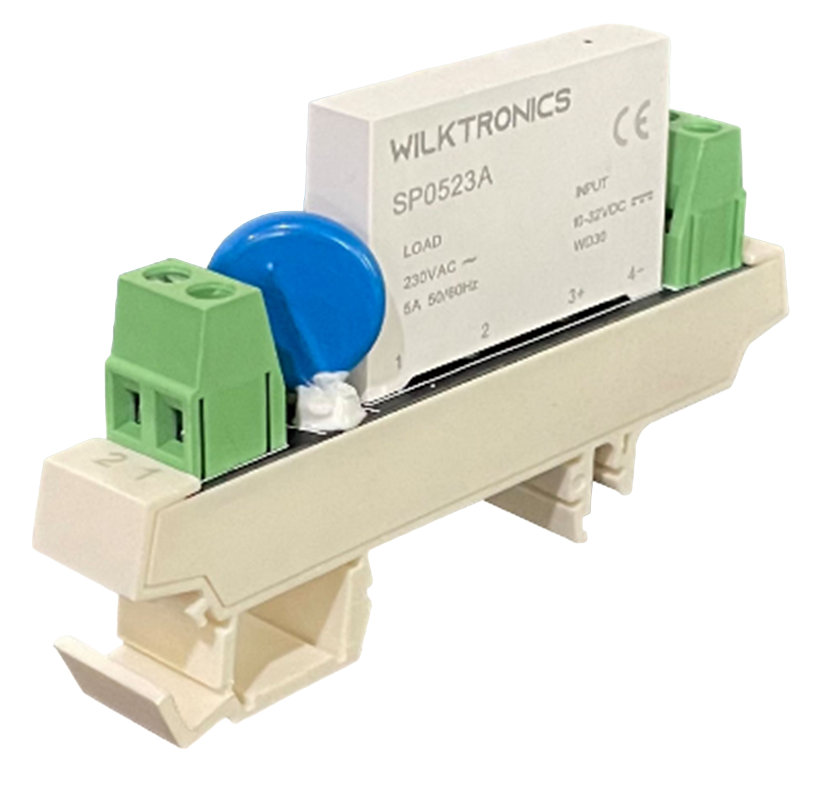

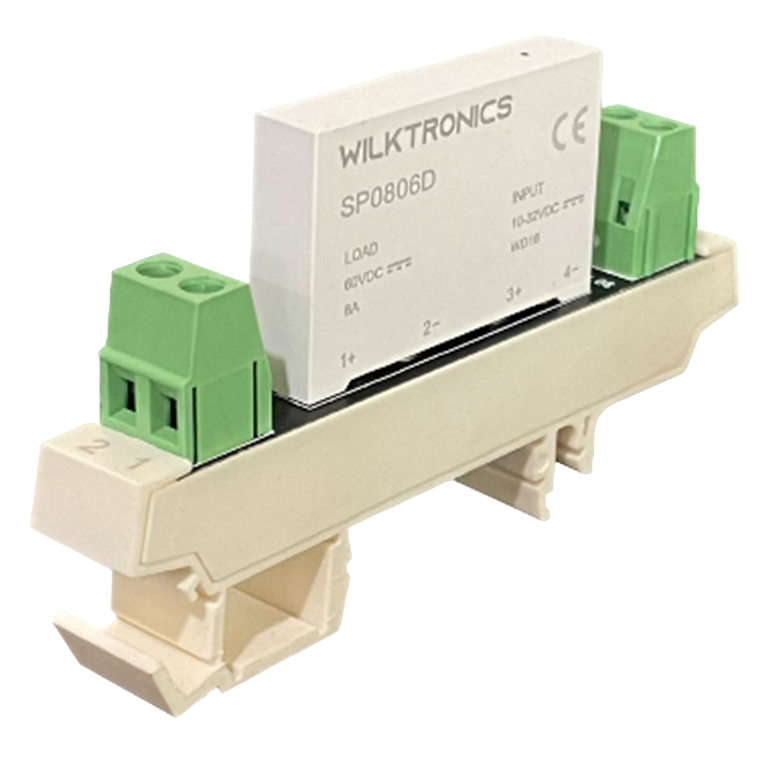

SP Series

The purpose of our Digital Solid-State Relays range is PLC interfacing. They are DIN Rail mounting, with Varistor protection on AC output versions.

Two output types 230Vac or 60Vdc and two output currents for each type. All driven with 3 to 32Vdc voltage, hence suitable for PLC outputs.

AC types are Zero Crossing Switching. Zero Crossing relays they turn output ON, despite when the input signal is given, only when the Output Voltage is crossing the 0. This technology avoids dangerous High In-Rush Currents on the output increasing load lifetime and protecting the relay itself

SR Series

In the realm of electrical engineering, innovation is key to progress and efficiency. The latest offering from Wilktronics—the Digital Hockey Puck solid state relays—stands as a testament to this pursuit of advancement. These relays are not just components; they are a leap forward in the control and management of electrical circuits.

The Digital Hockey Puck series comes in four robust zero-crossing output ratings: 25A, 40A, 60A, and 80A AC1 at 400Vac, all operable at a temperature of 25°C. This range of output ratings ensures versatility for various applications, from industrial automation to sophisticated electrical machinery.

One of the most striking features of these relays is their wide operating temperature range, spanning from -25°C to 80°C. This attribute makes them exceptionally reliable in extreme conditions, ensuring that they can withstand and function in environments that would challenge other relays.

Zero-crossing technology is another highlight of the Wilktronics series. This feature allows the relays to activate at the point where the AC power waveform crosses the zero-voltage point, significantly reducing electrical noise and wear on the relay, thus extending the life of both the relay and the connected components.

The Digital Hockey Puck solid state relays are designed with the future in mind. They cater to the needs of modern industries that demand precision, durability, and efficiency. With these relays, Wilktronics not only delivers a product but also provides a solution that could redefine electrical circuit management in various sectors.

For those interested in integrating cutting-edge technology into their systems, the Wiktronics Digital Hockey Puck solid state relays represent a smart and forward-thinking choice. Their robust design, coupled with advanced features, positions them as a crucial component for any setup that demands high performance and reliability.

Analog Solid State Relays

SRA Series

Our new series of SSRs boasts an impressive range of input and output specifications, with input signal 4-20mA, these SSRs offer precise control, ensuring seamless integration into existing control systems that utilize standard process signals.

The output capabilities of these SSRs are equally remarkable, ranging from 200 to 480Vac. This wide range allows for the accommodation of various load requirements, making these SSRs incredibly versatile. The series is available in four different current ratings: 25A, 50A, 75A, and 90A, providing solutions for both moderate and high-power applications.

Furthermore, the integration of analog input provides a smoother and more linear response to changes in the control signal. This results in finer control over the connected loads, which is essential in processes that demand high precision.

The applications for these SSRs are vast, ranging from heating control in plastics manufacturing to speed control in conveyor systems, and even in lighting control systems where large electrical loads are common.